Tools und Services

- Cost Finding / Price Finding **NEW**

- Supplier Profiling

- Total Cost of Ownership

- Freight Cost Calculation

- Make or Buy Comparison

- Corporate Licenses

- Seminars

News und Downloads

Where is the right price level ? Don't pay too much !

Do you know this szenario ?

You have to renegotiate an existing part or to negotiate a new part and there are certain price targets, regardless whether pre-determined by the Procurement Dept, by the Controlling or by the Marketing Dept.. However:

- You are not sure, whether the price target is possibly too high or whether there is - the other way round - even a much lower price possible.

- Although the sales manager tells you about "exploding material prices", you are not able to provide evidence which costs are there really and where should be the correct amount for the quote accordingly.

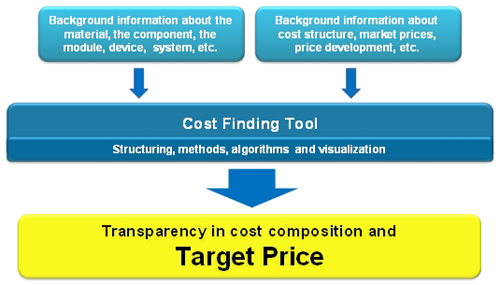

In this situation, our 8 different methods for cost finding and therefore price finding bring you decisive advantages:

Advantages:

- You can meet the supplier "at eye-level" and can demonstrate, which cost elements are there really and where should be the target price accordingly.

- You will be more successful in future price negotiations, you will be able to achieve significant price reductions (Experienced values: 3 … 8 % !) and contribute a signicant amount of added value for your company.

Typical Examples:

Unassembled PCBs very often can be bought in Asia with the same quality about 30 - 60 % (from total cost of view) lower in price.

How can you calculate the target price to +/-5 % accuracy ?

How can you provide evidence for a quote from Asia, which is in fact lower than your local quote, that the supplier has quoted "moon prices" ?

Drawing parts very often have very specific requirements regarding material, processing and the necessary expense of time to prepare and implement special processings. Since the quantities are often not that high, certain expenses, i.e. setup times can add up rapidly.

How can you estimate in an efficient way in the forefront whether the inquired quote is reasonable ?